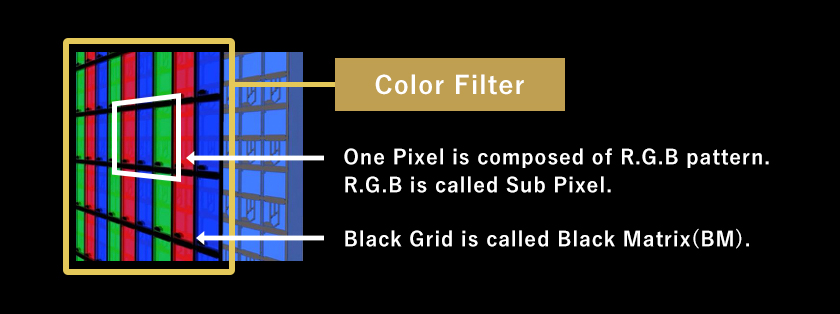

We introduce our system and process of LCD(Liquid Crystal Display) by videos and figures. Through these contents, You can see that our equipment supports the process of CF(Color Filter), or structure of CF, and about lithography, and inspection technologies.

CF creates colors of the image on LCD. This filter is composed of a thin glass substrate and color resist. Four color resists(R, G, B, BM) patterns are formed on a glass substrate. R, G, B patterns are formed into the grid or stripe by BM(Black Matrix).

- Photolithography process of LCD with a comparison of developing photos process-

The way of making a fine pattern on CF (Color filter) is similar to the method of developing a photo taken by the camera. First of all, clean the glass substrate (process01), apply photo-resist which hardens when exposed to light to coat the glass substrate (proccess02), and expose to light through a pattern-drawn photomask (equivalent to a negative film) and develop patterns on the glass substrate(process03, 04).

Pattern on negative film is transferred to photographic paper.

Photo paper is developed and dried.

Printing completed.

Master pattern on photo mask is transferred to glass substrate by Exposure.

Exposed substrate has a development and heat process after exposure process.

CF completed.

It's possible that there might be some defects on the CF substrate, for example, lack of color, a pattern defect, pattern size difference, and so on. Inspection, measurement, and repair systems are needed for the CF process to improve productivity and manage quality.

Inspection

Micrometer size defects can be detected by this inspection system with unique CCD cameras and microscopes.

Repair

Micrometer size defects can be repaired by the repair system. This system contributes to better production yield.

Total Pitch measurement

3m length can be measured with 0.01micrometer accuracy by this system.

*1micrometer= 1/1000mm

Visual Inspection

Large size defects, such as mura, uniformity, can be detected by visual inspection. This system support inspector to detect these defects efficiently.